Let's get started, the specifications on this VW Golf 5 GTi are as follows:

Model: 2008 VW Golf 5 GTi

Engine: EA113 2.0 TFSI 4-Cylinder Direct Injection (BWA)

Transmission: 6-Speed DSG (DQ250)

ECU: Bosch MED9.1

Location: THANAS JHB

The vehicle already had a substantially long grocery list of modifications when we started tuning it:

- Mambatek GTX3067 Turbo (Log Manifold) / Externally Gated

- GFB G-Force III Electronic Boost Controller

- Audi 8P S3 Injectors

- Audi RS4 rail valve (pressure release valve)

- Autotech HPFP Internals

- Custom Dual-LPFP Upgrade

- DO Water-Methanol Injection Kit

- Forged Motor Build (By Panic's Place)

- Upgraded FMIC & Piping

- Golden Tinfoil wrapped filter on a stick

- Custom DP & Exhaust

We logged the car, and after discussing the power goals in mind, the following upgrades were suggested, purchased and fitted to the car:

- Audi S3 (3 bar) MAP sensor

- 200 bar rail pressure sensor

- 165 bar rail pressure relief valve

These were needed to accurately log and account for boost pressure above the standard maximum of 2550 mbar absolute, or 1.55 bar gauge pressure (around 1.7 bar gauge at altitude). The biggest challenge on an EA113 TFSI is fuelling,and getting enough of it. The 200 bar rail pressure sensor as well as the 165 bar rail relief valve, allow for the rail pressure set-point to be raised well above stock, increasing the output of the injectors (more pressure = more flow), and the 200 bar rail sensor allows the ECU to compensate for the rail pressure by adjusting injection duration.

With everything in place we got to work building a custom ECU and TCU tune for the car. The tune consisted of the following:

- Scaled in S3 Injectors

- Scaled in S3 MAP sensor

- Scaled in 200 bar rail sensor

- Scaled in Autotech HPFP geometry

- Calibration for all of the above for increased rail pressure

- Adjusted LPFP controller mapping for custom LPFP setup

- Adjusted for Ethanol blended fuelling

- Adjustment of VVT mapping for quick spool and top end power

- Adjustment of fuelling and ignition timing mapping

- MAFless coding

- Injection timing optimisation for knock suppression

- Torque model calibration for high torque output to the DSG

We then calibrated our Stage 3 DSG mapping with the following edits:

- Torque limiters raised

- Auto-Upshift disabled

- Kick-down disabled

- D - Mode shift tables optimised

- S - Mode shift tables optimised

- Decreased shift times

- Maximised clamping pressure (up to 675 Nm on stock clutches, depending on condition)

- Clutch cooling adjustment

- Variable launch control rpm

- Launch with ESP active

- Maximum RPM raised

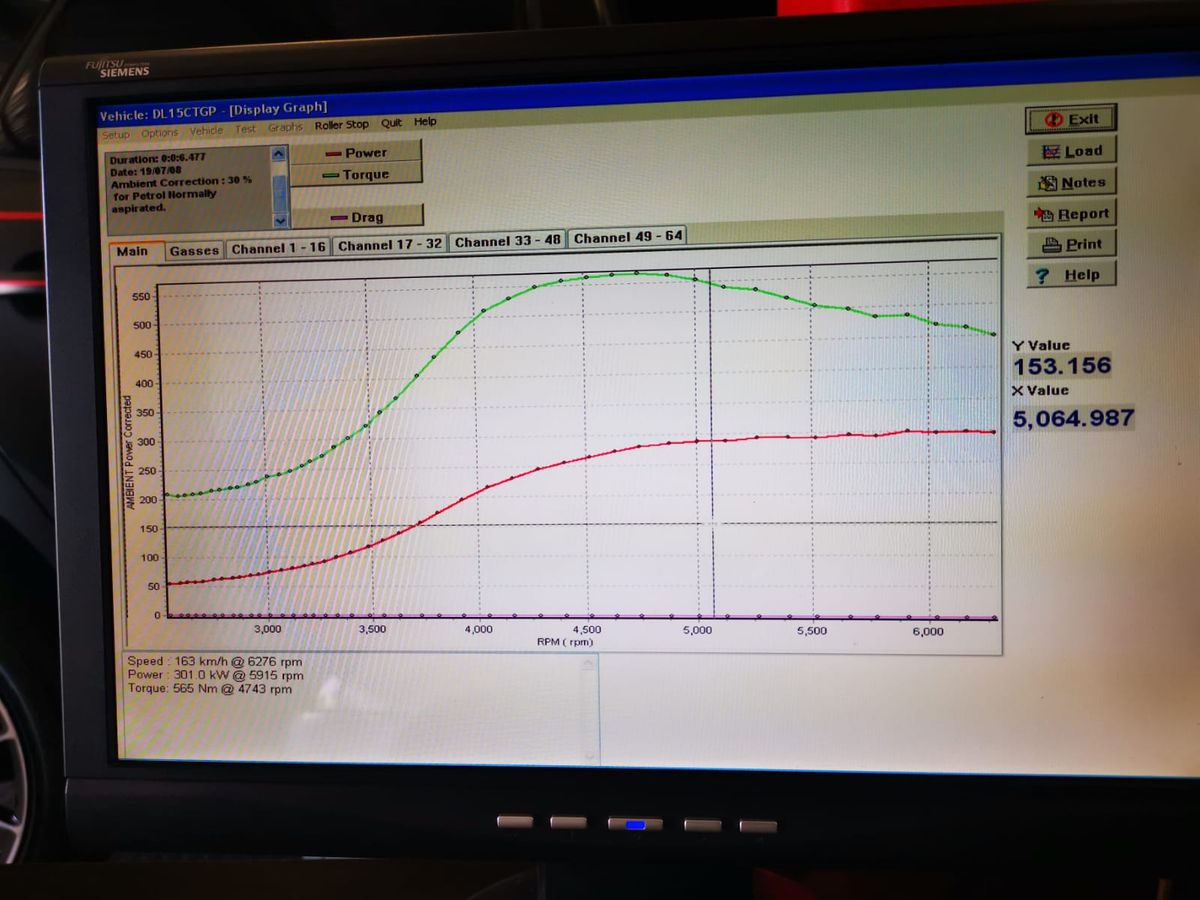

With all of that done, the ECU and TCU tunes were tweaked during the logging and revision process, making the most of what the relatively small .AR BT was capable of, and at moderate boost we managed a very respectable:

Power: 301 wkW / 404 wHp (404 - Boost not found)

Torque: 565 Nm

With the initial tuning done, we decided that more boost and power was needed, and with limited fuelling, the best way to increase power is to relieve back-pressure and pumping losses, and upgrade the turbo. The turbo was swapped out with a slightly larger GTX3071, and should be back on the dyno soon for more.

Thanks for reading, and if you haven't already, sign in with your thanas account or facebook details and click the notification button to be notified of new blog posts.