After the inevitable bug for more power took hold (no surprises here), we wanted to begin testing our tunes and further development for the LITTCO (littleturbocompany) IS38 hybrids that we were selling. So a Littco L380X was fitted, tuned and tested (fantastic turbo), however we won't be covering that part of the build under this thread, and will instead cover the L380X under a different build (#Evin).

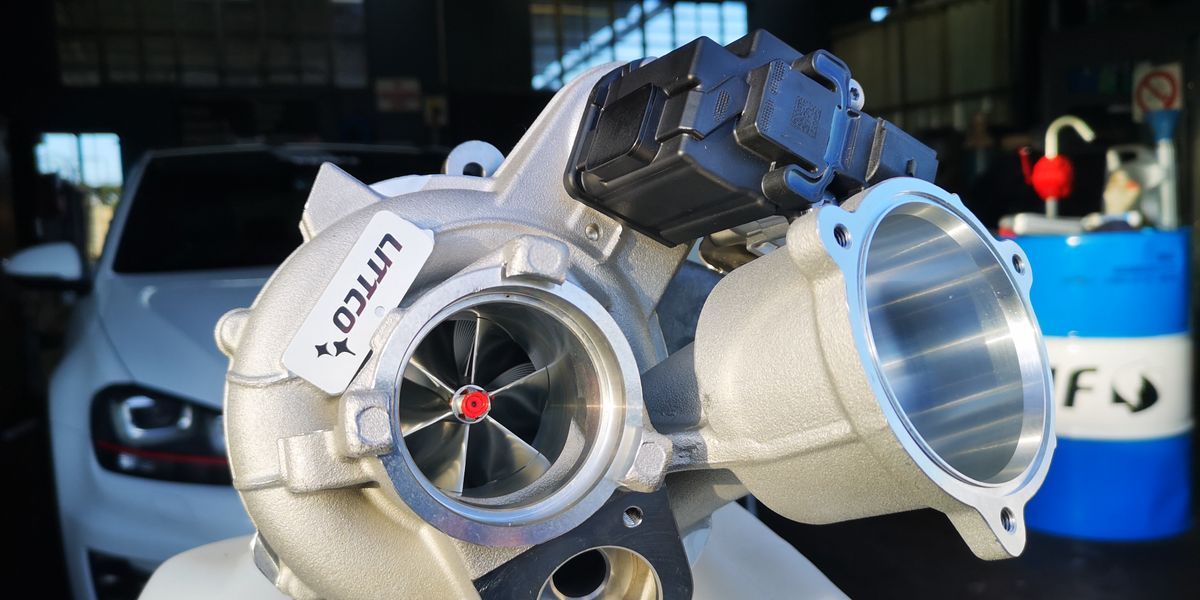

We opted for the Littco L500, the largest offering from the Littco catalogue, it features:

- 54mm exclusive billet compressor wheel; (Note: we opted for the taller, 6 + 6 high-flow wheel)

- Custom turbine with a 9 bladed high flow profile;

- Custom made turbine housing, made specifically for us and made in the same stainless steel material as the original;

- Custom compressor cover, made of solid aluminium ( no oem insert);

- CNC machined housings to exact specifications;

- Upgraded thrust bearing (144% increase in size and load area);

- VSR balanced above OE standards.

Why didn't we go for the Littco L450? Well because 500 > 450 :), and having already tested the L380X, we wanted to test the big-boi.

Some pics of the L500:

That's one sexy snail:

The turbo was installed by our Cape Town partner and THANAS Software dealer, J2 Performance, with new gaskets, o-rings, oil and coolant, and we set about mapping it for the larger turbo.

At this point we were still running the stock intercooler, and completely stock exhaust (except for the downpipe). Lockdown came into effect, and the setup was run like this for a good 5 months or so. When the restrictions started to ease up, we installed our large Mk7 GTI Front-mounted Intercooler Kit, as well as performing a little custom edit to the stock exhaust to get it to flow more, while retaining the OEM drone killing ability.

We tried out a custom 76 mm exhaust, but the drone was unbearable, so we reverted to the stock (+-63 mm) system. At the current power level, it certainly is a restriction, but for a daily driven car, the drone from the 76 mm system (even with 3 boxes) was excessive. This is in part owing to the design of the system, the quality of local mufflers, and the larger, much more open turbine wheel setup.

Some pics of the FMIC kit:

It's the biggest possible FMIC that we could fit, and it works insanely well. So well that we now offer it as a purchasable kit. From 60-70 deg IATs after a 1-5th gear run to 35 deg at the same 25 deg ambient temp, the results are evident.

We added two WMI bungs (to be used at a later stage).

The downpipe was wrapped and a Forge turbo blanket installed to keep under-bonnet temps under control. The top-mounted design of the EA888.3 puts an enormous amount of heat into the engine bay.

A custom 76 mm intake elbow was added at this point as well, connecting the VWR600 airbox to the Littco Large bore inlet elbow.

The car was run in this form, on the same initial custom tune we had done before lockdown, however as soon as we started to up the boost to where the party really starts, we ran out of injector capacity. Those that know the EA888.3, know that the GTi comes with smaller injectors than the 7R / 8V S3, and we do not run excessively high rail pressure to increase the capacity, as it increases the likelihood of injector failure immensely.

Adding an Autotech HPFP at this stage would serve no purpose as the injector capacity and not the HPFP capacity had been exceeded, the stock HPFP is exceptionally capable at higher rpm, where the larger turbo is making power. The only way to increase injector capacity, is to raise the rail pressure. On previous generation 2.0T motors this is not an issue, as they run either 110 bar or 150 bar stock (EA113 / EA888.1/2 respectively). However the EA888.3 found in the Mk7 already runs 200 bar rail pressure from the factory.

We also do not rely on WMI or external fuelling to augment the stock fuelling system. So to avoid risking the injectors or motor, we used our previously developed MPI (Multi-Port Injection) fuelling upgrade solution.

We removed the stock MPI injectors and replaced them with our upgraded units, and coded them into the ECU, setting the blend between the Direct Injectors and Multi Port Injectors to suit the application. In stock and 99% of tuned applications, the MPI injectors are only used at idle and very light load, and turn off completely under boost. We adjust this to ensure that all 8 injectors are spraying under boost, with a blend split of our own specification. The result is exceptional atomisation, especially at higher rpm, where overstressed DI injectors can result in misfire around the 6000+ rpm range.

This gives us much more fueling headroom than 7R injectors would, and will allow us to run high-ethanol content fuel in future.

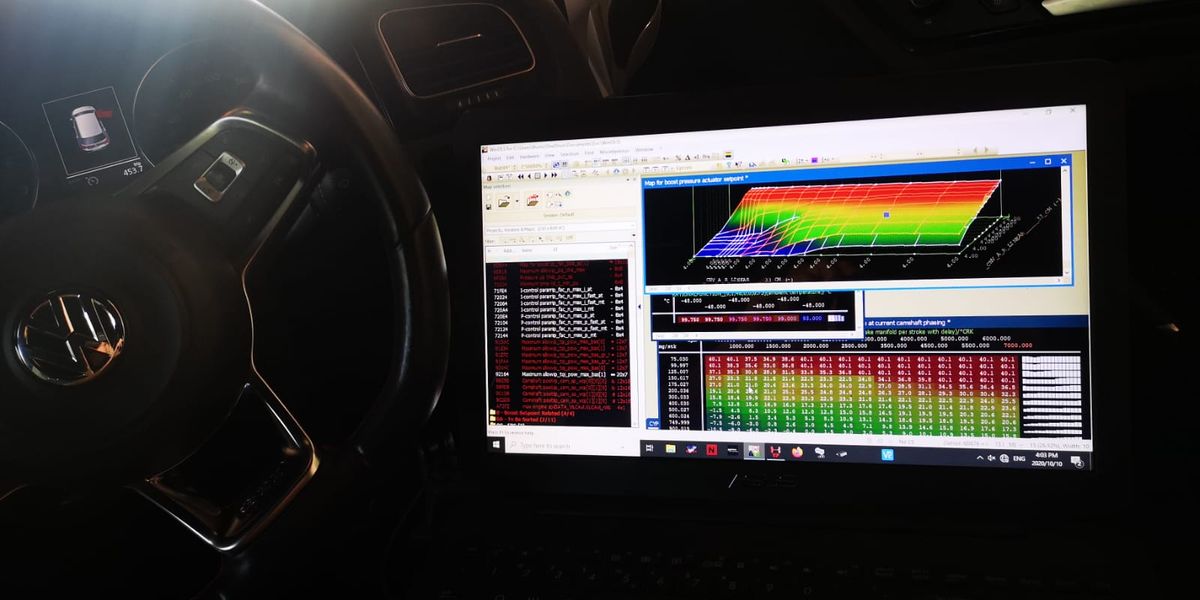

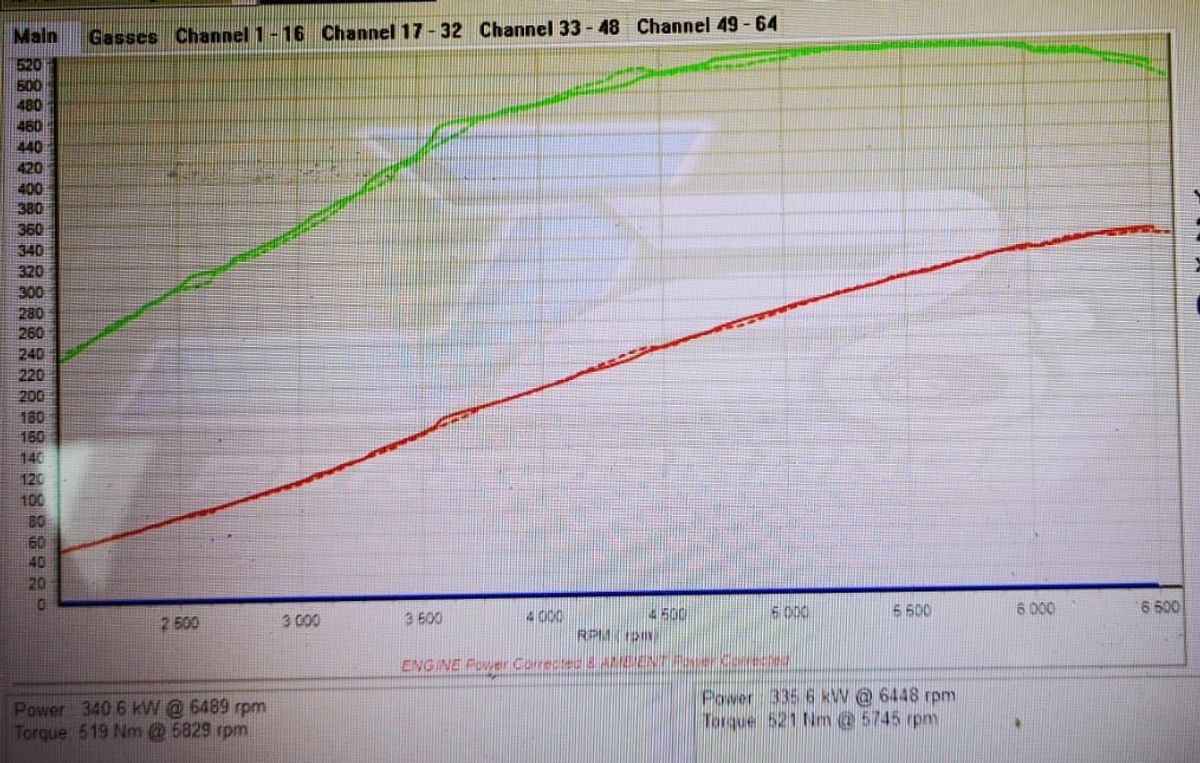

After some initial road calibration, the car was put onto the dyno at J2 Performance:

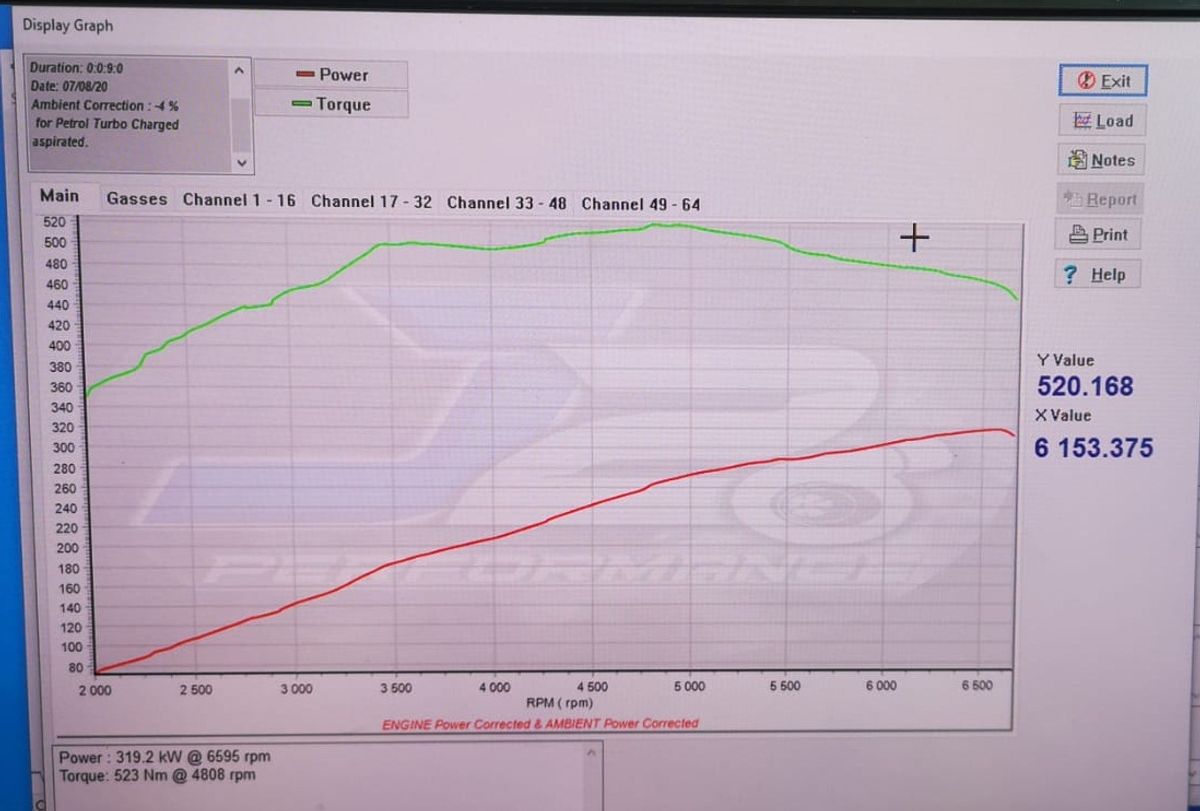

The setup made 319 kw and 523 Nm on the first run, on pure 95 octane. We didn't want to run much more torque, as the J2 Dyno is known to be very torque conservative, reading up to 100 Nm less than other dynos. And as the motor is still stock, we wanted to keep it 'rod-safe'. We ran through a few more revisions to smooth out the curve following this run.

However, going into summer, we wanted the octane of the fuel to be sufficient to ensure consistent performance in the higher ambient temperatures, as well as ensure the charge cooling matched the airflow and power. J2 Performance installed a snow-performance kit that we supplied, to assist with cooling. We personally don't run Methanol in our development cars owing to the toxicity factor, so we started off with an Ethanol-Water blend run through the WMI system, but eventually dropped the setup for pure water on a much smaller nozzle size, combined with a mild (E20) ethanol blend in the tank.

After some more dyno tuning, developing a slightly higher octane, ethanol based, stock motor map for the L500:

340 kW and 519 Nm at 6500 rpm was the end result, maximising power all the way to redline, while keeping torque at a safe level. At this point the low-pressure pump started to drop off, we decided this was a safe place to stop, and this is how it's been run ever since, with many, many boosted mountain runs. Driven hard almost every time it's taken out, the way a GTi is meant to be driven.

We're definitely not done yet, the LPFP will be upgraded and we'll aim for the 372 kw / 500 HP mark :)

Some general shots:

Thanks for reading, and be sure to follow our social media pages for more content.

Cheers.